6 Basic Gear Types and Know Their Uses

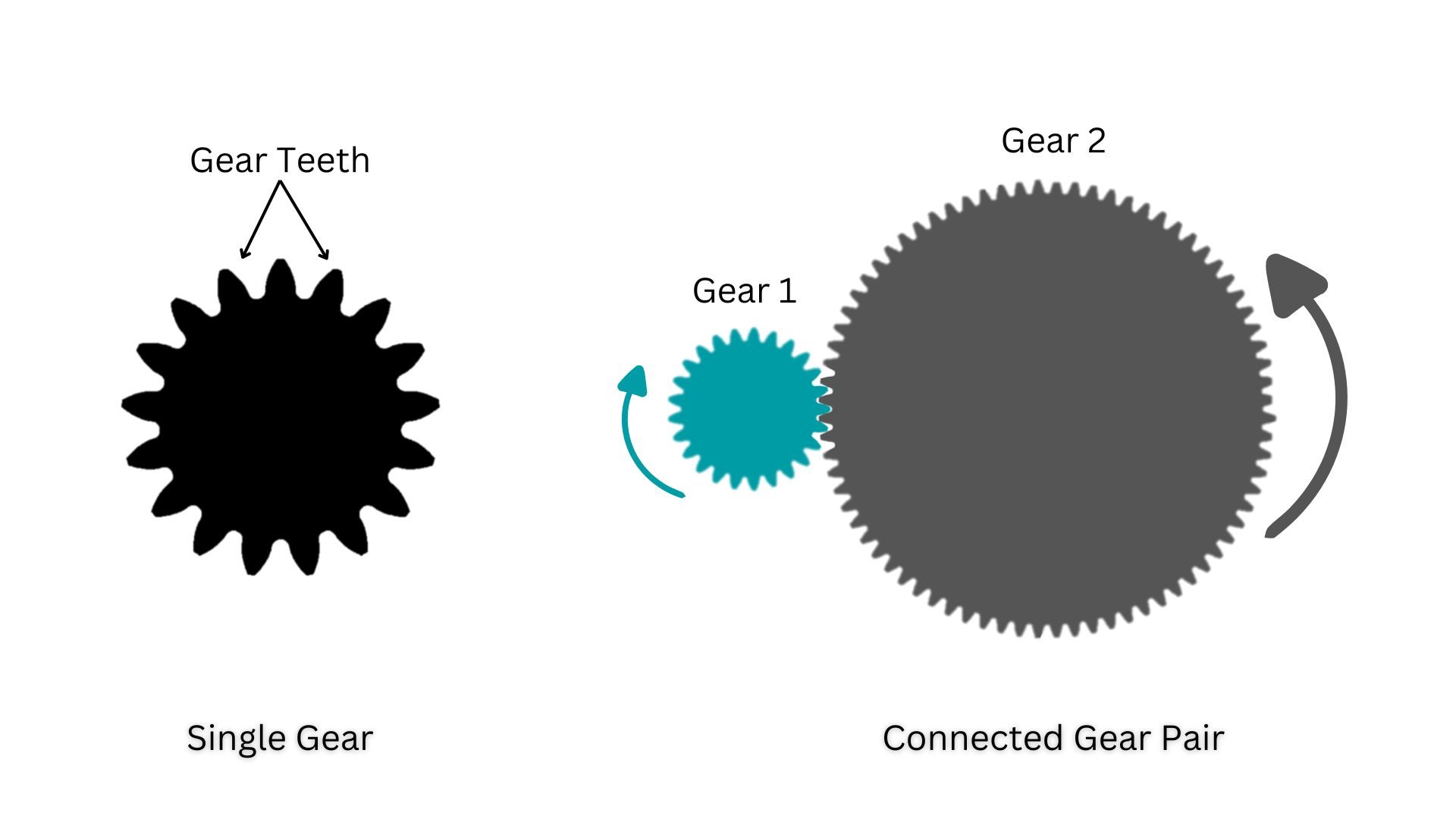

Gears are used to transfer the power from one point to another point, These are the mechanical components connected by the contact of teeth. we will learn about the different kind of gear types in this article, so let’s start with the example.

Gear 1 is the input for the rotational power and Gear 2 is the Output for rotational power.

Table of Contents

Importance of Gear

Why do we need the Gears, Let’s understand the basic requirements for using gear types with the below reasons,

Reason 1: When we need to transfer the power from one axis to another axis

Reason 2: It converts the Torque or RPM of the gear, for example if motor provides the 4000 RPM but the required RPM is 2000, so here we can use the Gear pair with gear ratio of 2:1, Let’s take dive into complete calculation.

Motor Torque: 150 Nm, Motor RPM: 4000

No. of Teeth : 17 (Gear 1), 34 (Gear 2)

Gear Ratio: 34/17 = 2

Calculating Output Torque and RPM >>

Output Torque: Motor Torque x Gear Ratio = 150 x 2 = 300 Nm

Output RPM: Motor RPM / Gear Ratio = 4000/2 = 2000 RPM

Classification of Gears

There can be different gear types on different aspects, so we will understand the gear types as per their configurations.

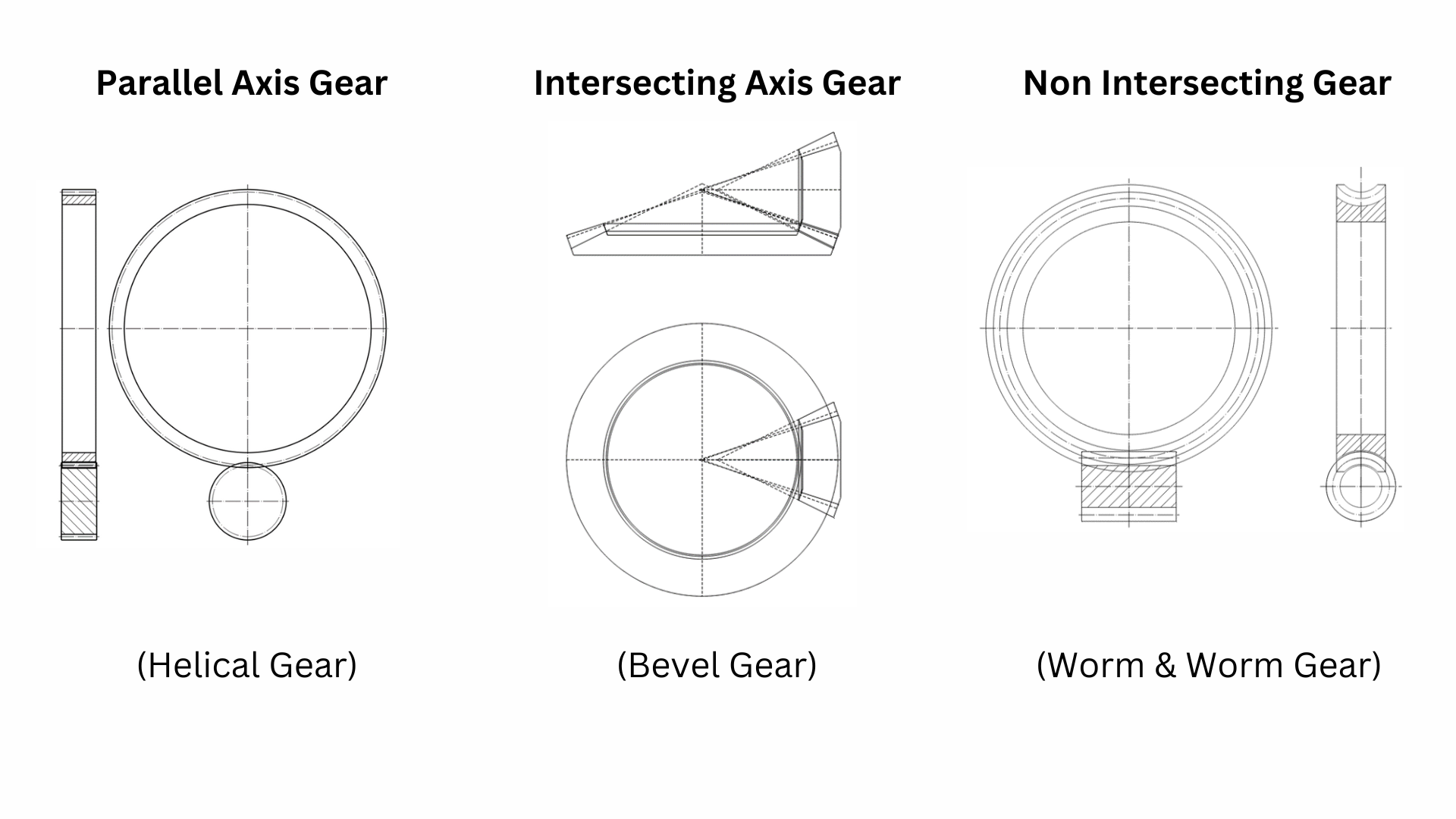

A) Based on Axis Configuration

1) Parallel Axis Gears: These gears are used when shafts are parallel

2) Intersecting Axis Gears: These gears are used with shafts that intersect at a certain angle

3) Non Parallel & Non Intersecting Gears: These are used when shafts are neither parallel nor intersecting

B) Based on Tooth Profile

Two types of gear tooth profiles are used, Let’s understand gear types on basis of their tooth profile.

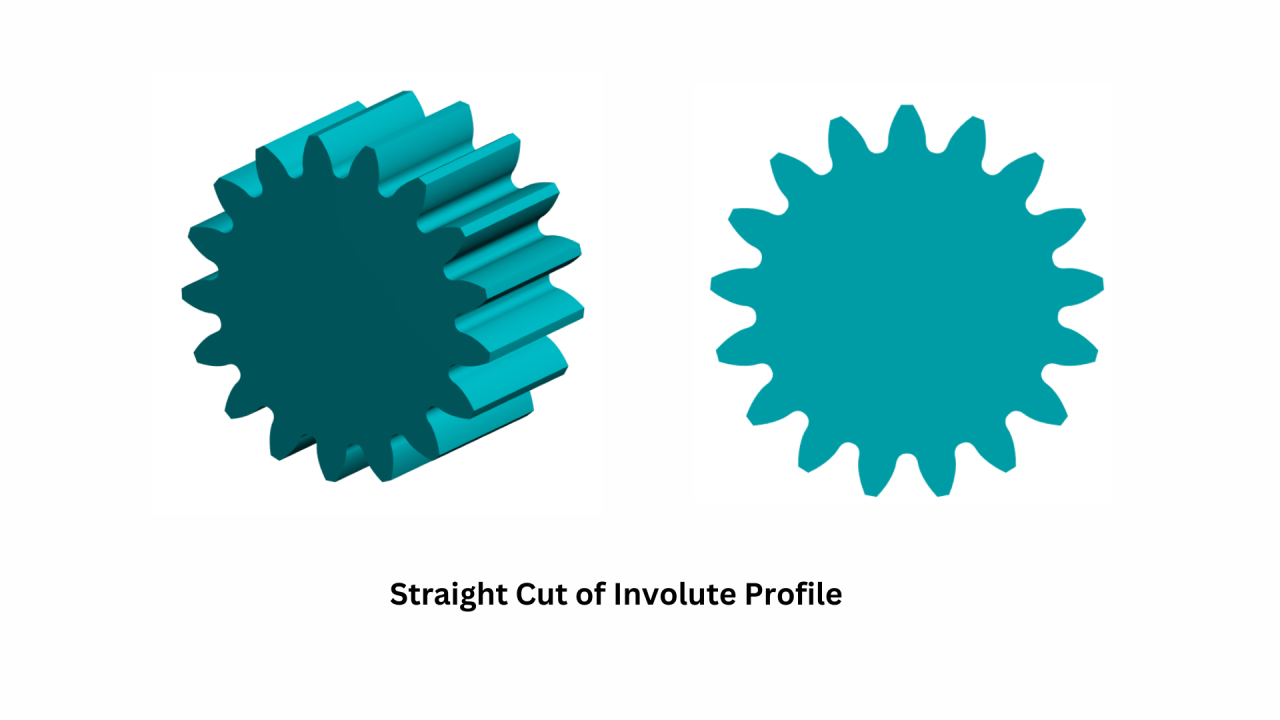

- Involute Profile Tooth: This type of profile is most widely used in the industry like Automotive, Machinery tools, Robots, and Ships and they are known for their constant velocity ratio.

- Cycloidal Profile tooth: This profile uses specific applications like Clocks.

C) Based on Load & Size

- Micro Gears: Tiny gears used in electronics or precision instruments.

- Heavy-duty Gears: Large gears found in industrial machines that handle significant loads.

Spur Gears

Spur gears are the most simple and common gear types, having straight-cut teeth on a parallel shaft. They have easy production and efficient power transmission due to their simplicity.

Advantages: It is very efficient and easy to design and manufacture.

Disadvantages For high speed, the spur gears are noisy because the teeth easily contact each other.

Applications: It is widely applied in machinery such as gearboxes and automobile transmissions where speed reduction is necessary.

Helical Gear

Helical gears are the same as spur gear types, but they have advantages due to angled teeth, which ensure a quieter and smoother operation because of gradual engagement.

- Advantages: Helical gears can carry more load than spur gears and operate smoothly, drastically reducing noise and vibration.

- Limitations of Helical Gears: Helical gears produce axial thrust; hence bearings for support are necessary.

- Applications: These gears are used in high-speed and heavy-load applications like automobile gearboxes, elevators, and conveyors.

Bevel Gear

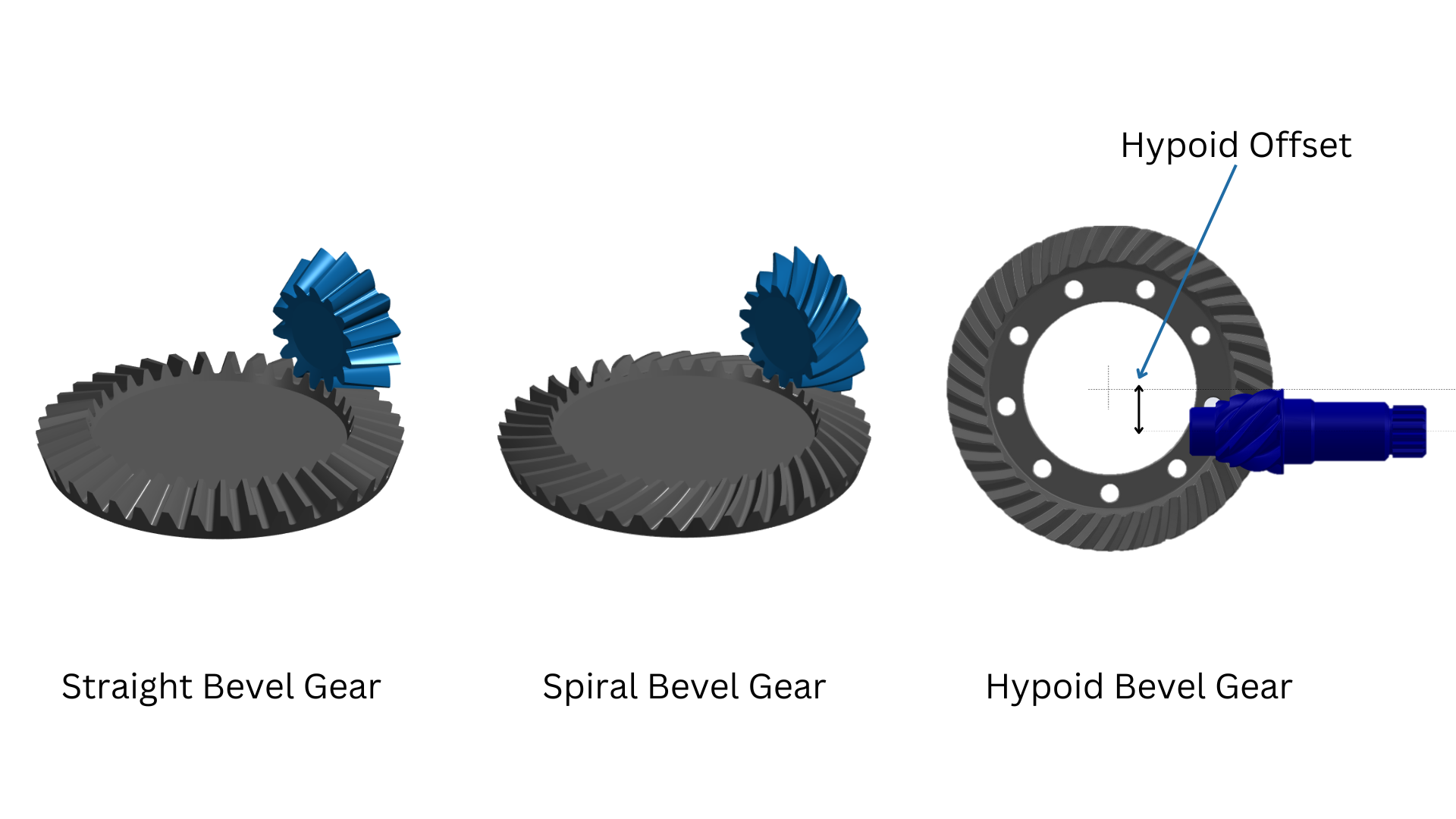

Bevel gears are gear types which are conical in shape. They transmit motion when intersecting shafts are required. Bevel gear teeth designs can be straight or curved.

There are further Bevel Gear types, which are as follows,

- Straight Bevel Gears: Simpler design but noisier operation.

- Spiral Bevel Gears: This gear provides a quieter operation and better efficiency because of gradual tooth engagement.

- Hypoid Bevel Gears: Used wherever shafts are not intersecting.

Some applications of differential systems include industrial machines as well as the use in hand drills where power is transmitted between perpendicular shafts.

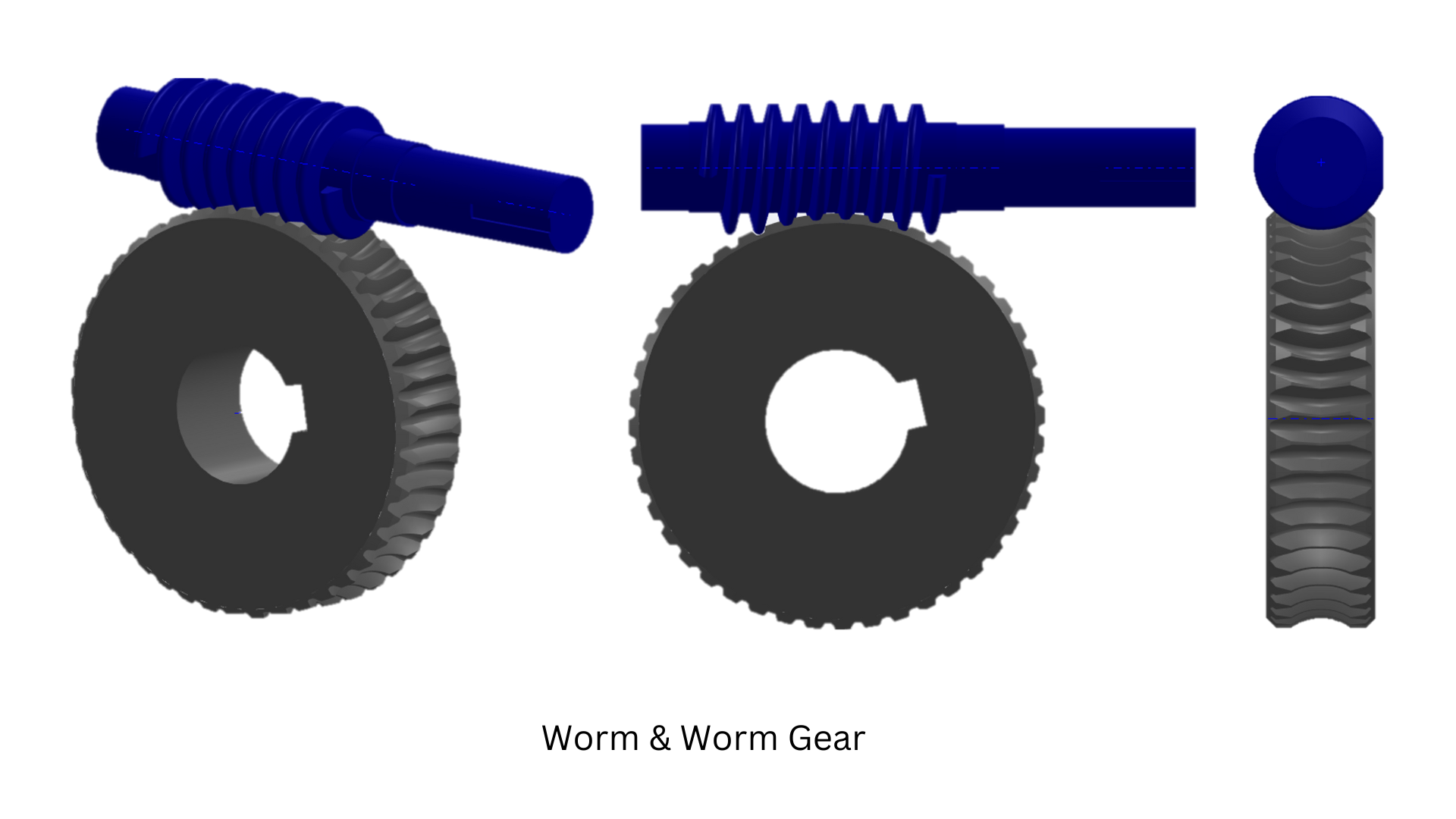

Worm Gears

A worm gear consists of a worm that resembles a screw-like gear, meshing with a worm wheel. This gear types is unique for having a high reduction ratio and the ability to lock the drive when the worm is stationary.

Advantages: Great reduction ratio in a compact form; self-locking ability in certain cases.

Low efficiency of gear since friction is lost.

Applications: This gear is used in systems where a reduction in speed and increase in torque is desired, such as an elevator, conveyor, and steering mechanism.

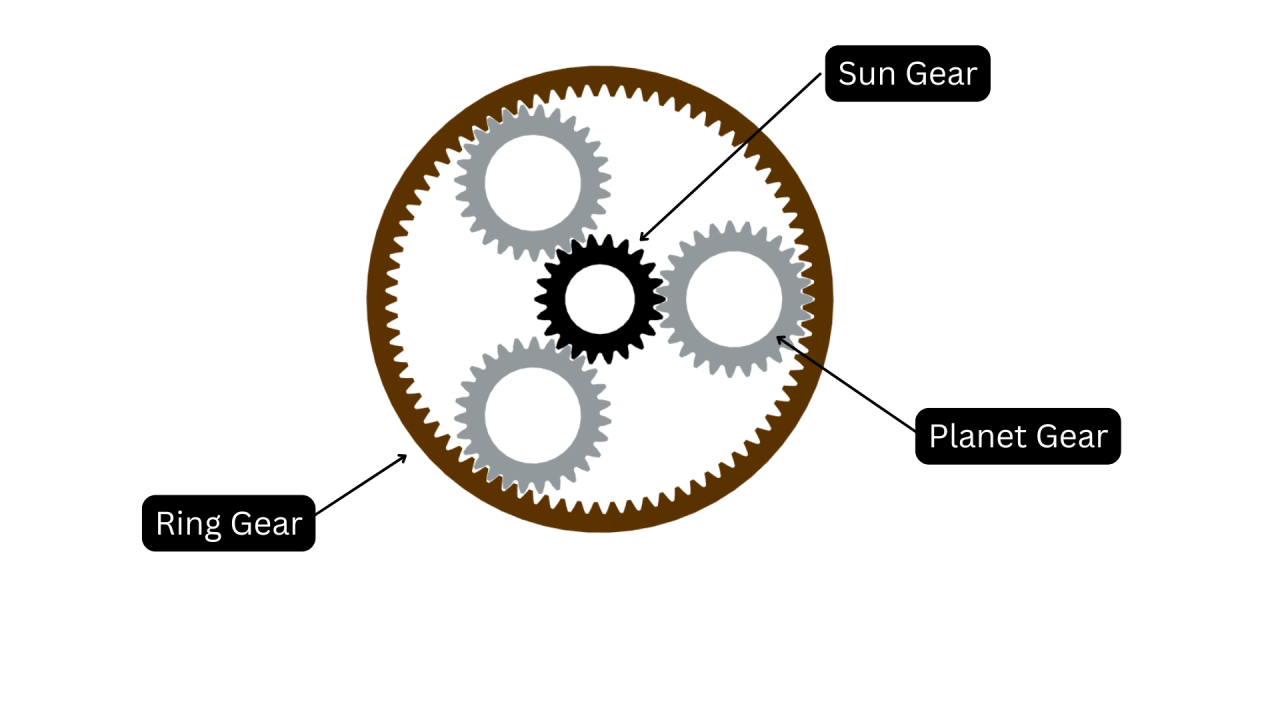

Planetary Gear

A planetary gear system is also referred to as an epicyclic gear system. It includes three main components: the sun gear, the planet gears, and the ring gear working in a compact harmonious manner that provides higher torque with varied control over speed and multiple configurations makes planetary gears the most widely used in many high-performance applications.

Components of a Planetary Gearset:

1) Sun Gear: A sun gear is the central part of the gearset. It is the driving wheel through which the power is received by the planet wheels. The planet gears mesh with the sun wheel. In a planetary gearset several planet gears usually three or more surround and engage the sun gear. These planet gears revolve about the sun gear simultaneously while rotating about their own axes.

2) Ring Gear: The ring gear is another term for an annular gear. It refers to the outer, circular gear, thereby encircling the entire system. Its inner teeth engage those of the planet gears. Ring gears are typically fixed but can be made to work as output elements of power, given the type of configuration of the gear.

3) Planet Gear: The planet carrier supports all the planet gears and serves as a kind of rotation axis for the planet gears. In many configurations, it connects to the output shaft. The torque from the planet gears is shared among the output that helps the system have very high torque efficiency.

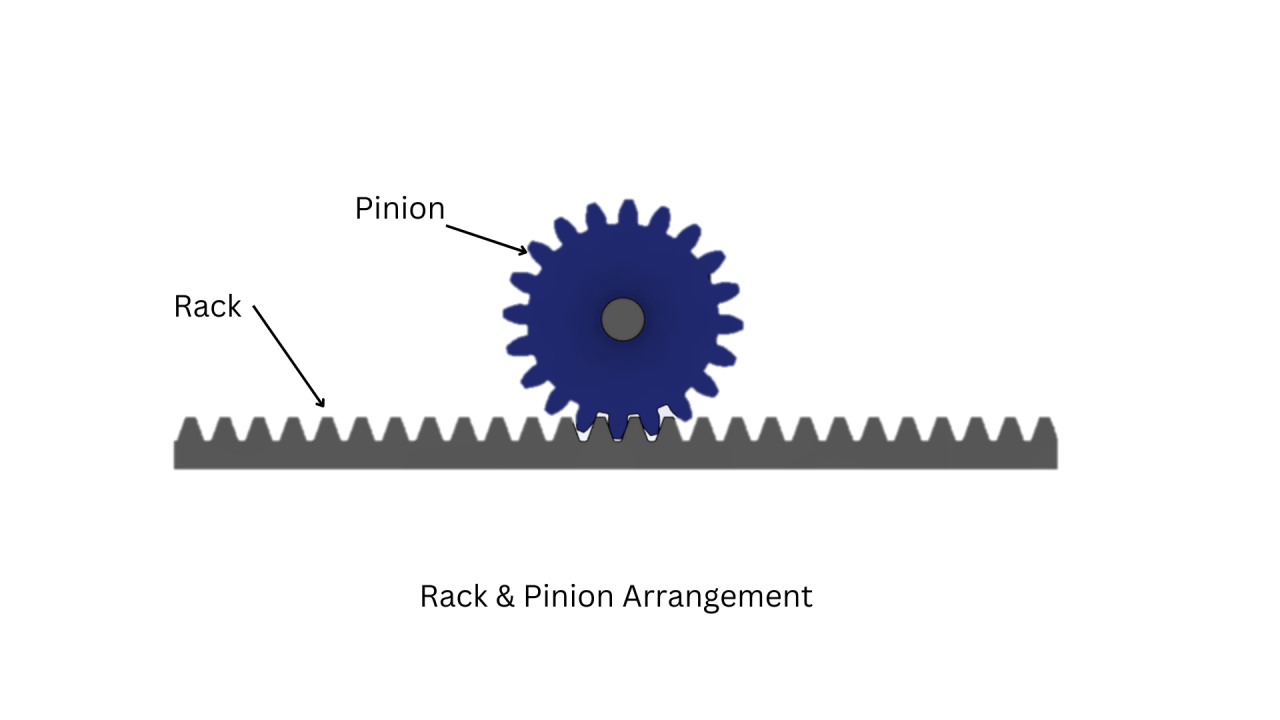

Rack & Pinion Gears

The rack and pinion gear system translates rotational motion into linear motion. It consists of a round pinion gear that accepts a linear rack for movement along a straight path.

Applications: This is commonly applied in vehicle steering, linear actuators, and rail transport systems. These are applications that offer controlled motion in machinery.

Applications of Gears in Various Industries

The applications of gears are about every industry:

Automotive Industry: The power transmission inside vehicle transmissions and differential systems employs the essential gears.

Aerospace: Aircraft has the most precise gear system, for its control surfaces, landing gear, and also propulsion.

Industrial Machinery: Gears can be found in cranes, hoists, and equipment for manufacturing high-duty gears.

Robotics: Gears drive robots to move with smoothness and great precision, especially when performing some actions as if it were a joint and limb.

Renewable Energy: Gears play a crucial role in wind power generation to be utilized in converting wind energy into electricity.

Future of Gear Industry

Gear technology keeps on advancing with time as more industries require better performance:

Material Science Advancements: New, lighter-strong materials are developed for gears, like high-strength composites and alloys

Manufacturing Innovations: Technologies such as 3D printing and CNC machining have enabled gears to be produced with more precision and customization.

Sustainability: Environment-friendly gears are now designed using biodegradable lubrication and energy-efficient designs.

Conclusion

Gears are one of the integral parts of new machines. Every type has a purpose it serves. Starting from simple spur gears in daily machines to sophisticated planetary gears in robotic machines, choice between them plays an important role in efficiency, reliability, and levels of performance. As we move ahead in the technology of gear-making, it will be advanced, using different kinds of materials and designs to scale new heights for these crucial components.

You can also read the article about Why Every Car Needs Gearbox.